Self sealing closures and sealing insert closures

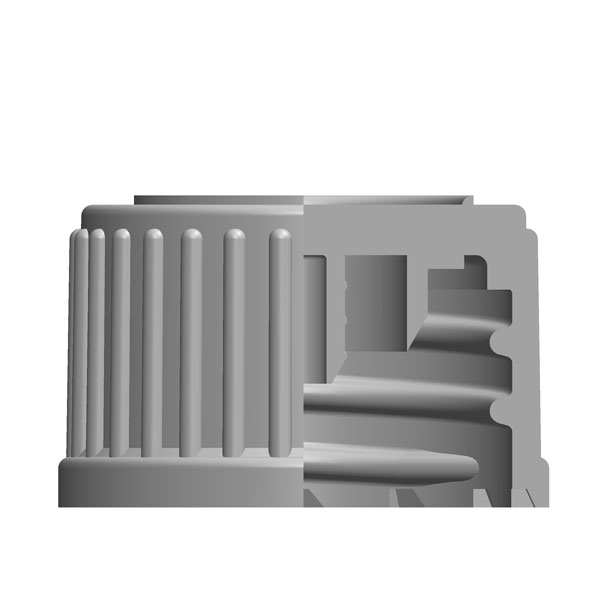

Self-sealing closures

Self-sealing caps, also known as linerless sealing or conical sealing closures, are the simplest and most cost-effective method of sealing bottles. During the injection moulding process, the closure is equipped with a conical sealing lip inside the cap. The cap is actually sealed by the closure itself without any further components being required, such as liners. As a consequence, they only require a single raw material specification. All Sensoplast closure types are available with self-sealing caps. Brushes or spatulas can be installed in these types of closures as necessary.

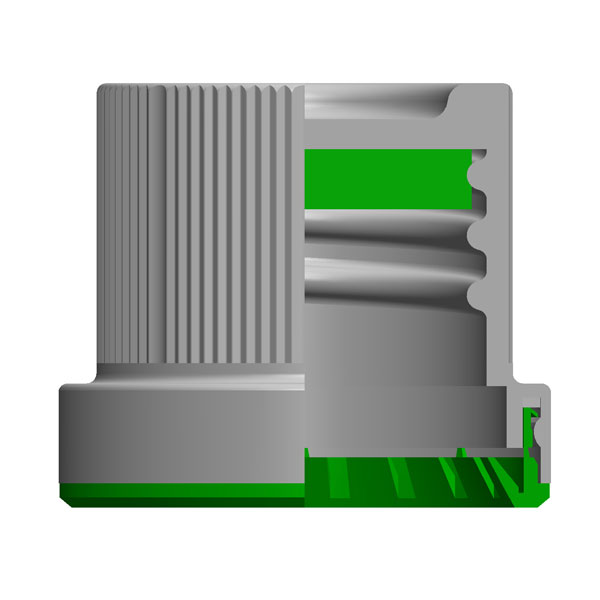

Sealing insert closures

A further simple method of sealing bottles is to fit the closure with a liner. We provide a wide range of liners made from different raw materials that can be supplied with or without lamination (such as aluminium, Teflon and many more). This enables the individual closure liner to be matched with the requirements of various types of fluid.

Self-sealing closures

Sealing insert closures

Facts

Thread variants:

- DIN 168 GL-18 (DIN 18)

- DIN 168 GL-22 (DIN 22)

- PP 28 (DIN 6094-7)

Types:

- Smooth liners made from EPE foam in various densities

- Smooth liners made from EPE foam laminated with aluminium, Teflon or other materials in various densities

- Conical liners made from polyethylene (LDPE)

Raw material:

- Self-sealing closures:

Polyethylene (HDPE) or polypropylene (PP) - Sealing insert closures:

Polypropylene (PP) or polyethylene (HDPE)

Highlights

- Universal applicability for various chemical compositions and viscosities of fluids

- Easy-to-use screw fastening